Pallet Racking Systems

We Are The Manufacturer With The Largest In-Stock Inventory!

We Have Everything You Need For Your Complete

Pallet Racking System!

We Are The Manufacturer With The Largest In-Stock Inventory!

We Have Everything You Need For Your Complete

Pallet Racking System!

$296.66 – $501.48

Select options

$296.66 – $501.48

Select options $436.88 – $723.14

Select options

$436.88 – $723.14

Select options $451.98 – $740.34

Select options

$451.98 – $740.34

Select options $307.60 – $514.64

Select options

$307.60 – $514.64

Select options $571.04 – $940.08

Select options

$571.04 – $940.08

Select options $710.20 – $1,224.74

Select options

$710.20 – $1,224.74

Select options $221.93 – $393.02

Select options

$221.93 – $393.02

Select options $328.84 – $574.99

Select options

$328.84 – $574.99

Select options $432.72 – $754.60

Select options

$432.72 – $754.60

Select options $539.10 – $968.07

Select options

$539.10 – $968.07

Select options $227.40 – $399.60

Select options

$227.40 – $399.60

Select options $336.39 – $583.59

Select options

$336.39 – $583.59

Select options

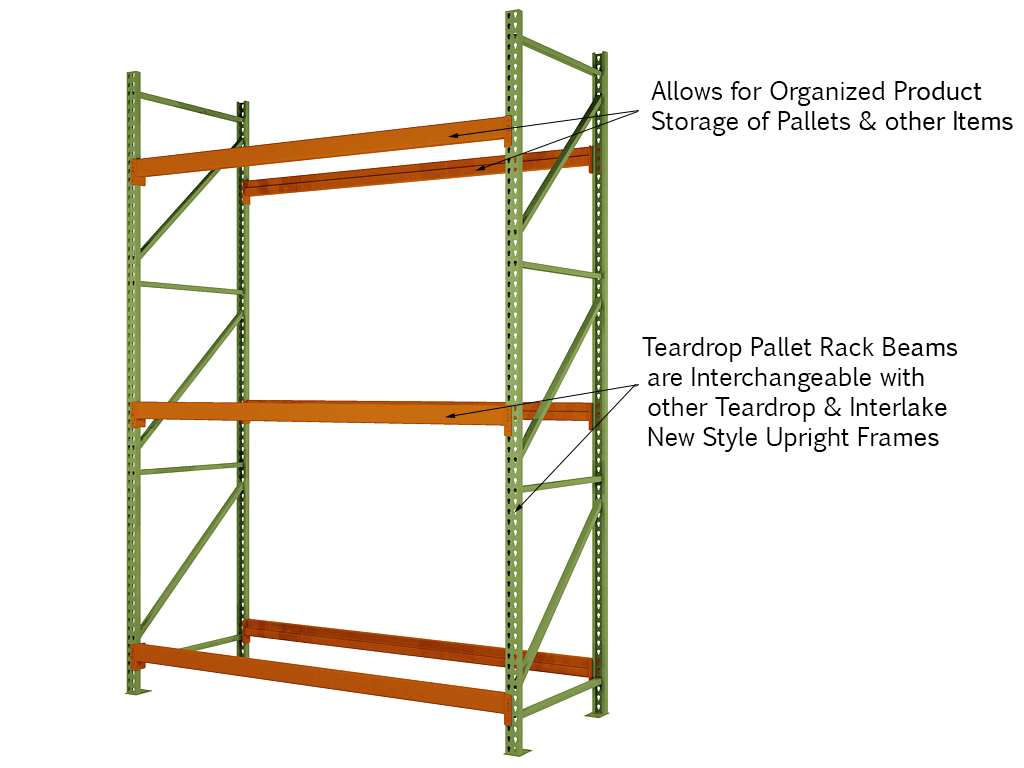

Conventional Racking Systems

A system consisting of steel uprights and beams to support some type of decking to store goods. These systems offer maximum flexibility because the strength, height and length of the bays can be varied during installation to suit the stored material.

Steel uprights are usually classified as heavy duty or light duty, and further subdivided by the style of the locking mechanism used to secure decking to the uprights. Common styles include teardrop and keyhole.

Decking for warehouse racking systems also varies depending on the need. Most warehouses have a combination of wire mesh, cantilevered and stationary decking made of plywood or other materials.

Selective Pallet Racking

There are many different pallet rack systems that you can employ in your warehouse. One of these systems is selective pallet racking, which is very flexible in nature and easy to set up. Selective pallet racking is one of the most commonly used systems for storage in a variety of applications. Learn more about the components of a selective pallet racking system as well as its benefits, and find out which circumstances work best for this system.

Only Material Handling Exchange offers all these benefits to warehouse operators, along with a team of experts who will help you choose the optimum pallet rack systems for your warehouse. Our company will help you optimize your warehouse layout within your budget, whether that covers new or used pallet rack systems.

Components of Selective Pallet Racking

In a selective pallet rack system, the vertical structure is the uprights. Beams are then attached to the uprights, and they hold the pallets. These can be installed at different heights and are available in different lengths; both of these factors will influence the capacity of your selective pallet rack system. The aisles in selective pallet racking can be either single or back-to-back. In a back-to-back system, bays that lie before and after one another will share uprights.

Benefits of Selective Pallet Racking

In a selective pallet rack system, the vertical structure is the uprights. Beams are then attached to the uprights, and they hold the pallets. These can be installed at different heights and are available in different lengths; both of these factors will influence the capacity of your selective pallet rack system. The aisles in selective pallet racking can be either single or back-to-back. In a back-to-back system, bays that lie before and after one another will share uprights.

Disadvantages of Selective Pallet Racking

Despite its popularity, selective pallet racking is not suited to certain types of applications. If you have a very high volume inventory, selective pallet racking can make storage very expensive. In addition, the uprights in selective pallet racking cannot be any higher than about 40 feet. Finally, selective pallet racking takes up a large amount of your available space. If you have very large products or require more storage space, selective pallet racking may not be for you.

Creating Your System

To create your selective pallet racking system, first measure the products that you will be storing. Determine not only height, depth, and width but also weight. With the measurements of your products and pallets, you can determine the necessary width of your bays. Next, you can also ascertain the necessary depth of your uprights and the number of rows your system can hold. After this step, you can determine the height of your system and the spacing of your shelves. This should take into account not only product dimensions but also other relevant factors in your warehouse, including the ceiling, lights, and sprinklers.

Pallet Rack Systems With a Purpose

Pallet rack systems for inventory storage and warehouse organization come in a variety of styles, with a nearly infinite number of configurations. Complicating matters further, pallet racking systems can be purchased either new or used. Used pallet rack systems can be an economical solution, since as long as the steel components have not been exposed to weather or harsh environments, they will last nearly forever.

Benefits of the Right Pallet Racking System

Pallet rack systems are one of the most powerful influencers of warehouse efficiency. When the wrong warehouse racking systems are installed, it takes longer to find, store and pick materials. Material handlers may have to waste time traveling throughout the warehouse to gather materials stored in distant locations. Using the wrong type of warehouse racking system can also create a dangerous safety hazard.

Even if you are looking to buy used pallet rack systems, it’s important to work with a company that knows and understands warehouse operations. The company should offer consulting help to recommend the right pallet rack systems for your product mix. It should also have ample inventories of a variety of warehouse racking systems; while offering both new and used pallet rack systems for purchase with quick delivery. The company should ensure that used pallet rack systems have not been stored outside — because exposure to weather can lead to rust, which weakens the steel of warehouse rack systems.

Don't see what you're looking for?

Chances are we have it in stock today and can ship it immediately!

What Our Customers Are Saying

Past Customers

Our Affiliate Companies