Cantilever Racks

Buy Direct – We Manufacture Top Quality Structural Cantilevers.

Largest selection of new & used Cantilever Racks.

Guaranteed lowest prices in the Nation.

Buy Direct – We Manufacture Top Quality Structural Cantilevers.

Largest selection of new & used Cantilever Racks.

Guaranteed lowest prices in the Nation.

Free Warehouse Layout and Design.

$40.03 – $62.58

Select options

$40.03 – $62.58

Select options $40.03 – $62.58

Select options

$40.03 – $62.58

Select options $46.36 – $74.57

Select options

$46.36 – $74.57

Select options $46.36 – $74.57

Select options

$46.36 – $74.57

Select options $39.65 – $74.57

Select options

$39.65 – $74.57

Select options $46.36 – $74.57

Select options

$46.36 – $74.57

Select optionsIf you are looking for New or Used Cantilever Racking system for your warehouse or outdoor storage facility look no further. MHE has over 1,000 of Beams, Towers, Bases and Starter Bays on site at our location. From time to time we acquire complete cantilever rack systems never installed and never used. This gives you the quality of new product at the price of used cantilever racks.

Compared to selective pallet rack designs, items are more accessible meaning easier forklift loading and retrieval. All of this equates to a significant increase in storage capacity and handling efficiencies.

There are over 1,000 variations of cantilever racks positions and storage options we can offer. Most people are not sure if they need inclined or straight beams and/ or what lengths while maintaining the stability to hold product. Give us a call and one of our staff of highly trained, experienced pros can help you understand what size, load capabilities, beam lengths and warehouse layout you will need to maximize your space for storage.

You may find it useful to know that cantilever racking systems are available to accommodate especially stressful loads, such as those common in the steel industry. In such super-heavy duty designs, the columns are manufactured from high strength steel, then tapered to compensate for column deflection, and pre-punched on both sides for conversion from single to double-sided rack units. Further, cantilever arms also are tapered to compensate for deflection, and the steel base is welded to the column to provide a stable foundation.

How to Build a Cantilever Rack System

How to determine the quantity and spacing of your cantilever arms

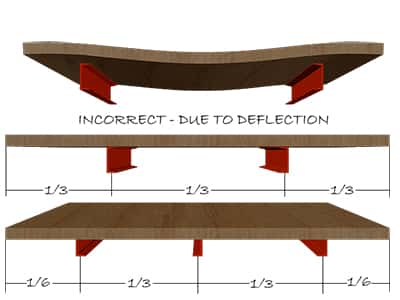

It is important to use enough cantilever rack arms under the product in order to prevent and/or minimize deflection of the material being stored. Deflection of your product can lead to damage to product. In some cases this will cause undesirable pressure refereed to as “Side Pressure” on the arms. To determine the proper quantities of arms required to adequately support your materials without any deflection is simple. Start by taking 2 wooden blocks or perhaps some 2 x 4’s and place the wood on the floor. The you take your product and place it on the wood to test the material / load for deflection. This test will help you determine if your material being stored can be supported by two arms. You can adjust the width between the wood until you begin to detect any deflection. It is a general rule of thumb and a good idea to never space the arms farther apart than 1/2 the length of the material you are storing.

2. Once you start to detect any deflection of your material, then you will have reached the maximum distance that your arms can be apart in your cantilever racks. Always choose a measurement that is based on even numbers since the brace sets come in 2 foot wide to 8 foot wide in most cases. Please don’t forget the rule of thumb of not having your cantilever arms spaced more than 1.2 the length of the material being stored.

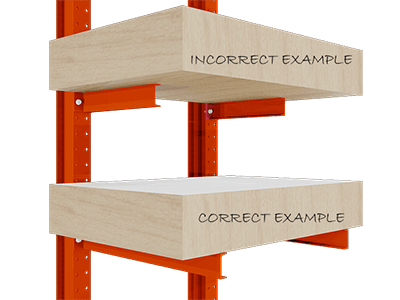

3. If deflection is seen when using Two (2) arms then try Three (3) arms under your material. When you are correctly loading your racks, the product should only overhang the arms by 1/2 of the cantilever upright center-line distance. It is incorrect and dangerous to load the products on the rack arms without overhang.

How to determine the right Cantilever arm length

How to determine the correct cantilever upright height

Steps to take next:

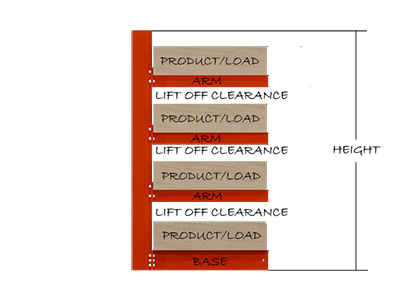

Give consideration to the cantilever racks base height and review the number of storage levels you can achieve reviewing the following:

How to Build Cantilever 3Load Height: This will be the total distance from where the material/product will rest on the Arms to the top of the product. It is important to give consideration to the minimum of 4″ of lift off distance required to safely place and remove your product off the arms with a forklift.

Arm Levels: Every arm level within the system will require a certain amount of space. Cantilever Arms all come in different heights because of their different capacity requirements. The average height is around 3-4 inches high. When laying out your system, simply give consideration to the height of your cantilever arms.

Cantilever Upright Height: It is a good rule of thumb to have the top of the cantilever upright 4-6″ higher than the top of the highest point of the product being stored. The top arm level must always below the top of the cantilever upright.

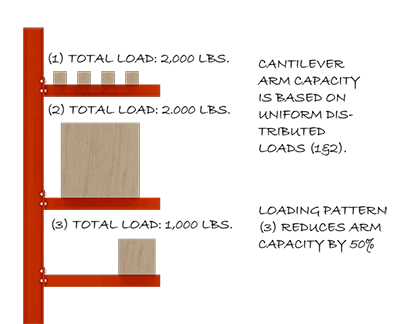

How to determine the required cantilever arm capacities

Take the Load/Product weight and divide it by the quantity of arms it will take to support the product without creating and deflection of the product itself. Capacities are determined based on a uniformly distributed load on the cantilever arms. Loading the arms unevenly can reduce their capacities by up to half.

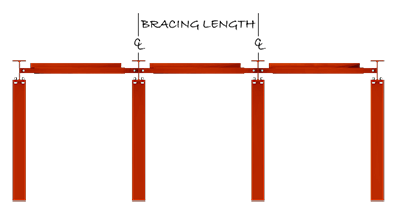

How to determine the Cantilever Bracing Lengths

The length of your rack braces refers to the distance between the On Center (O.C.) of the upright tower as shown in the diagram above. When determining the length that you need please refer back to step 1. The bracing generally comes in once piece brace kits or panels or in one piece horizontal braces.

Please feel free to call us today with any questions you may have when it comes to building just the right cantilever rack system for your specific storage requirements.

Don't see what you're looking for?

Chances are we have it in stock today and can ship it immediately!

What Our Customers Are Saying

Past Customers

Our Affiliate Companies